BlueCore Technology Co.,Ltd.

AI-Ready Solutions. Engineered for Industry.

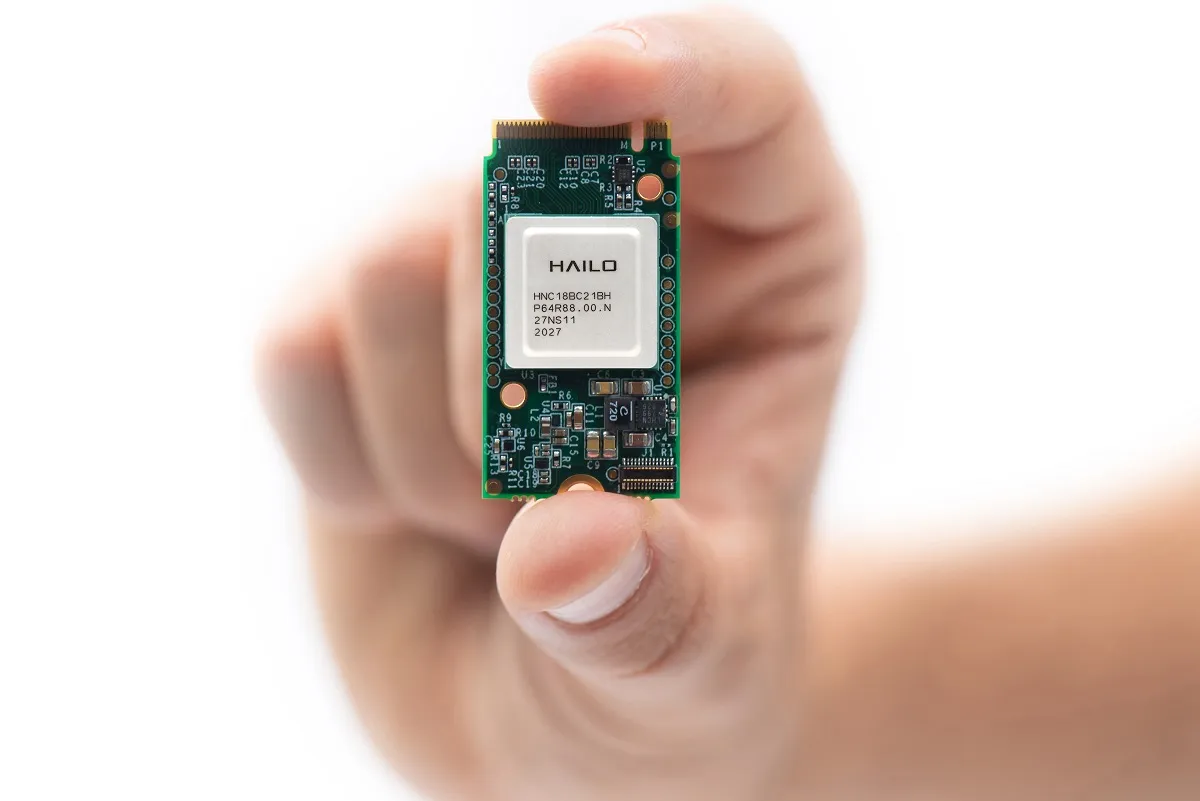

We are an innovative company based in Taiwan, specializing in AI-driven industrial Quality Control and Automation. We design high-performance solutions to enhance precision, efficiency, and uptime, streamlining production and eliminating hardware bottlenecks. BlueCore Technology specializes in developing cutting-edge industrial PCs that integrate seamlessly with AI systems for automotive production and manufacturing environments. Our solutions combine robust hardware engineering with intelligent software to deliver unprecedented performance and reliability.

AI Integration

Built-in AI processing capabilities for real-time decision making

Industrial Grade

Rugged design for harsh manufacturing environments

Scalable Solutions

Modular architecture for growing production needs